Soy Proteins by Membrane Technology

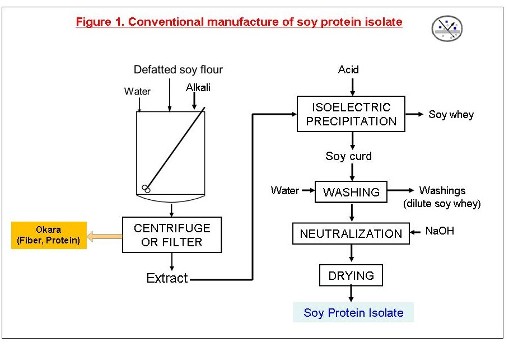

Soybeans (18-20% oil, 45 – 50% protein) are the major source of edible oil in the United States and an important source of plant protein ingredients. After the oil is removed, the defatted soybean meal is used as animal feed and is the raw material for soy protein concentrates and isolates. Figure 1 shows the most common method of producing soy protein isolates by dual pH adjustment.

The initial alkaline extraction steps are similar to any protein isolate process. Defatted soy flour is extracted under optimum conditions of temperature, time, flour-to-water ratio and pH. To produce isolates (90% protein), the fiber and insoluble components are removed by centrifugation or filtration of the extract. The underflow from the centrifuge (or the filter cake) can be re-extracted if necessary (not shown in Figure 1: see Figure 4). After acid coagulation at the isoelectric point, the acidic mixture is separated by filtration or centrifugation into two streams: (i) a light phase containing soluble components including soluble protein (which could amount to 20-30% of the nitrogen in the soybean), sugars, soluble salts, etc.; this is termed “soy whey” and is usually dried and sold as animal feed, and (ii) a heavy phase containing the precipitated protein/soy curd which is washed with acidic water and separated again, resulting in more soy whey (“washings” in Figures 1 and 3). The protein is resolubilized by adding NaOH and dried.

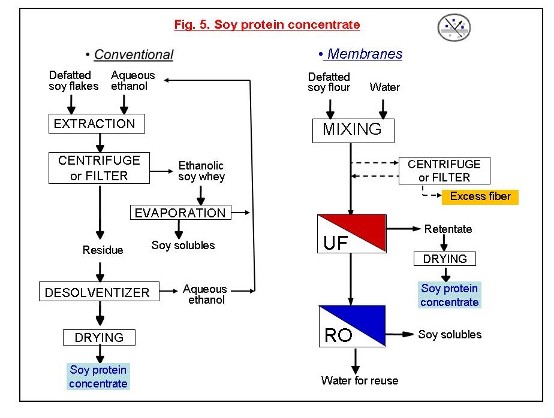

If a soy protein concentrate is required, the defatted soy flour is mixed with water and acid (instead of alkali) and the pH adjusted to the isoelectric point of the proteins. Alternatively, the defatted soy flakes are extracted with aqueous ethanol (60-90% etanol). This is shown in Figure 5.

Membrane processing of soy proteins

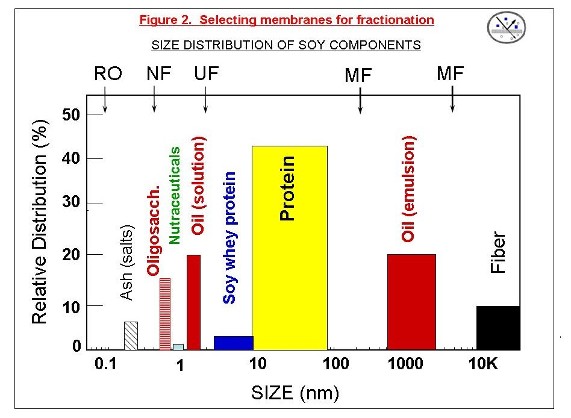

We have developed alternate processes for purifying vegetable proteins and removing many objectionable compounds using membrane technology. Since the undesirable oligosaccharides, phytic acid and some of the trypsin inhibitors are smaller in molecular size than proteins and fat components, it should be possible, by careful selection of the membrane and operating parameters, to selectively remove these undesirable components and produce a purified protein isolate, concentrate or soymilk. This is shown in Figure 2 that shows the relative size distribution of various soy components and where a particular membrane could be used to separate two or more components, depending on the manner in which the raw material has been processed.

Recovery of soy whey proteins

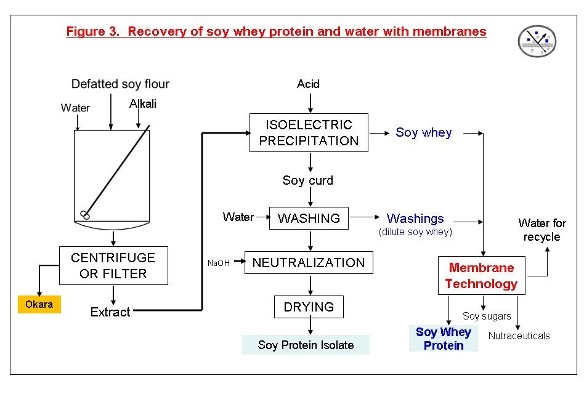

Membranes can be used in the conventional soy isolate (or concentrate) process to recover the soy whey proteins and simultaneously produce clean water that can be re-used within the plant. Soy “whey” is the liquid portion remaining after the proteins (and fiber) have been removed from an extract, usually by isoelectric precipitation (Figures 1 and 3). The whey contains water, protein fractions, sugars (oligosaccharides), phytate, salts, isoflavones, saponins and other acid-soluble minor components. Soy whey is dilute, with 0.2-1.5% total solids, depending on the process. The whey is sometimes further diluted with the washings.

The whey proteins are soluble even at acidic pH and have good functional properties; it is unfortunate that they are lost in the whey during conventional isolate manufacture. [The membrane methods shown later in Figures 4 and 5 do not result in a loss of whey proteins: they are part of the retentate and thus included with the products]. However, even in the conventional soy isolate process, the whey proteins can be recovered with membranes from the whey and/or the washings. The membrane will concentrate and purify the soy whey proteins by filtering out the non-protein components, most of which fortunately are much smaller in molecular size than the proteins. The result will be a high-protein, highly functional and economically valuable coproduct that has hitherto been wasted.

This is shown in Figure 3. The soy whey and washings are combined (pasteurization may be needed to control microbial growth) and processed with a combination of ultrafiltration and reverse osmosis/nanofiltration membranes, depending on the desired products. Ultrafiltration (UF) of the soy wheys will produce a high-quality protein fraction as the retentate while the UF permeate will contain the oligosaccharides and possibly other valuable compounds such as saponins and isoflavones. The UF permeate can be subjected to nanofiltration (NF) to separate one or more of these components, and reverse osmosis can be used to concentrate all the solids in the UF and/or NF permeates while generating good quality water. At the very least, it will largely reduce or even eliminate the discharge of high-BOD waste water from the plant.

Soy protein isolates and concentrates

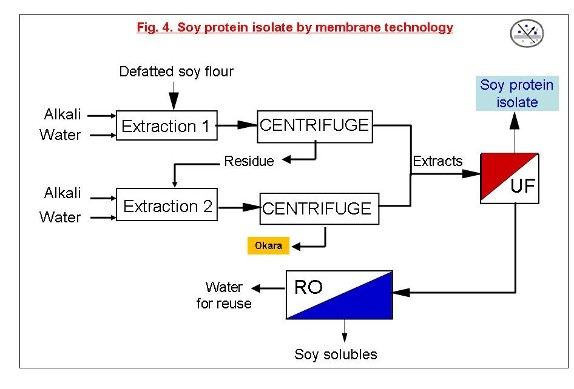

Figure 4 is a schematic for producing soy protein isolates from defatted soy flour using membranes. The four is mixed with water and alkali (usually NaOH) in the optimum flour-to-water ratio, temperature and pH, and mixed for the optimum time. After

separ ation by centrifugation or filtration, the heavy phase (‘Residue” in Figure 4 containing primarily fiber and some protein) can be re-extracted to increase protein yield. The combined extracts are ultrafiltered (UF) and diafiltered to remove soluble permeable components which are mainly the oligosaccharides and soluble salts thus increasing the protein content of the retained solids to 85% protein d.b. or higher. The UF permeates can be processed by reverse osmosis (RO) to recover the oligosaccharides while generating clean water for re-use or discharge.

If a concentrate is required, the defatted spy flour-water mixture (with no alkali or acid) can be directly ultrafiltered to remove the oligosaccharides. The retentate's final composition will approximate a soy protein concentrate (>65% protein d.b.). This is shown in Figure 5 which compares the conventional ethanol washing method to the membrane process.

Membrane soy isolates and concentrates will result in higher protein yield because the whey proteins are recovered in the final product. The membrane products should have better functional properties owing to the presence of the whey proteins and because no acid or ethanol has been used.

Soymilk with membranes

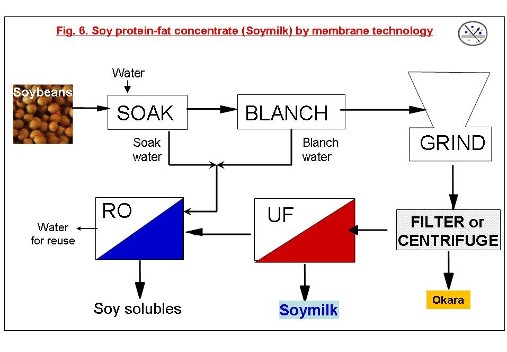

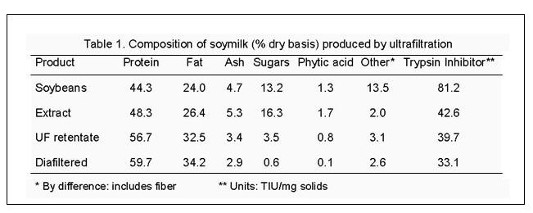

The process shown in Figure 6 can be used to produce a soymilk with an excellent flavor profile, lower trypsin inhibitor, reduced off-flavors and low in phytic acid and oligosaccharides. Whole soybeans are soaked and then blanched to prevent lipoxygenase-induced off-flavors during grinding. The first separation step (filtration or centrifugation) serves to remove insoluble carbohydrate and fiber and ensure the particle size is appropriate to the membrane being used. Ultrafiltration of these water extracts with 20,000 -500,000 MWCO membranes have been reported in the literature beginning in the 1970s. The composition of the soymilk we obtained with a 50,000 MWCO membrane is shown in Table 1. Using membranes with higher MWCO changed the final product composition and yield and results in higher flux.

___________________________________________________________________________________

References:

Cheryan,M. 1998. Ultrafiltration and Microfiltration Handbook, CRC Press, Boca Raton, FL.

Publications on this topic

Publications on this topic