ZEIN: THE PLANT-BASED INDUSTRIAL BIOPOLYMER FOR THE 21st CENTURY

Protein in corn (maize, Zea mays) forms about 9% of the dry weight of corn. The major protein in corn is zein which comprises about 40% of the total kernel protein. It is a storage protein known as a prolamin containing a relatively high level of glutamine and proline. It is highly hydrophobic and insoluble in water under normal conditions, but is soluble in alcohols such as aqueous isopropanol or ethanol and in acidic and highly alkaline solutions. Other proteins in corn include glutelin (soluble in alkaline aqueous solution), albumins and globulins. Prolamins are also found in wheat (gliadin), barley (hordein), rye (secalin), sorghum (kafirin) and oats (averin), in addition to corn (zein).

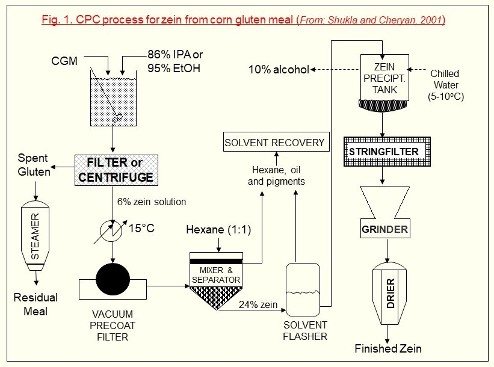

Zein was first discovered by Gorham in 1821. Osborne developed the first patented process for extraction of zein using 95% ethanol from corn gluten meal (CGM) which is a co-product of the corn wet milling industry. Swallen et al. were granted a series of patents in the 1930s and 1940s on zein production using different alcohols of varying concentrations and additives on which some commercial processes were based as shown in Figure 1.

Zein became commercially available in 1938 and quickly found application in coatings, fibers, films, plastics, adhesives and inks. Zein (often combined with vegetable oils and/or glycerin as plasticizers) was used as a waxing or glaze, to enhance shelf life of pharmaceutical tablets, nuts and candies by acting as a water and oxygen barrier. This was part of the chemurgy movement where crop/farm by-products were utilized by industry. Zein fibers with the commercial name of Vicara was produced by the Virginia-Carolina Chemical Corporation in 1948. It was marketed for its claims of washability, the warmth of wool and resistance to moths and mildew. Zein reached a peak production of 7 million kg per year in 1956 but with the development of cheaper synthetic materials, the market for zein dropped significantly by 1960. By the beginning of the 21st century, there was one known manufacturer of zein in USA and one in Japan. The cost of zein is $20-70 per kg depending on the grade and purity. Selected applications of zein are shown below:

Food and Medical Uses

• Used as a coating and as a product for encapsulation for flavor and medicine

• It has good resistance to microorganisms, heat and humidity and can conceal the taste and odors of a pharmaceutical

• Used as a fat-mimic to replace 50-100% of the fat in mayonnaise, ice cream and spreads. Zein hydrolysates have very high water-binding capacity and can inhibit (ACE) activity which reduce blood pressure

Gums and Coatings

• Excellent shellac substitute, from candy coatings to paint additives. Shellac is an animal protein secreted by insects (Laccifer lacca).

• Chewing gum base will not stick to shoes, carpet, a child’s hair or a school desk.

• It is biodegradable and has “GRAS” status

Films and Packaging

• Zein forms excellent films and coatings due to its unusual solubility pattern and structure

• Made by blown extrusion

• Films are thin (200 microns)

• Flexible

• Glossy

• Translucent

• Transparent

• Low permeabilities to oxygen and carbon dioxide

• Can form an edible moisture barrier on fruits and vegetables to extend shelf life three weeks and up to three months for mushrooms and fresh pasta

• Edible hay bale wraps for the livestock industry

• Horticulture mulches and ground cover

• Unlike plastic, zein sheets are biodegradable which means reduced labor and disposal problems.

• Biodegrade in the soil and acts as a slow-release nitrogen source.

Industrial Uses

• Make biodegradable polymers using bio-based plasticizers such as fatty acids and vegetable oils.

• Grease or water resistant

• A natural adhesive and binder

• With a cross-linking agent can be compression-molded to produce water resistant plastics

• Can be used to make bottles, pipes, rods, laminates, sacks and bags

• Used to coat aircraft engines, as a support for electrophoretic deposition of brazing materials with conducting polymers successfully provide electromagnetic applications

• Forms brick-like nanostructures which can be used as a framework for growing human skin cells. This technology is useful for wound dressings for burn victims.

The COPE Project

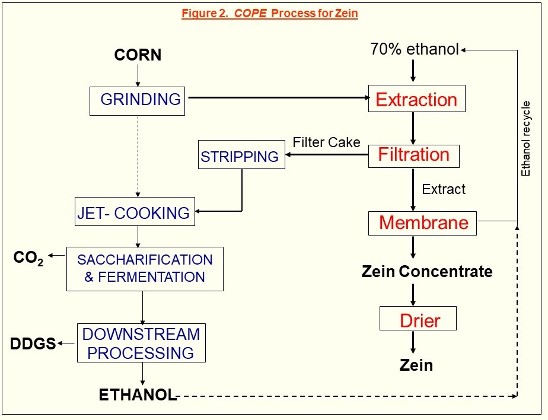

We developed alternate methods for producing highly functional zein for the food and industrial markets. Our COPE (Corn Oil and Protein Extraction) process uses ethanol for the initial extraction of zein from corn or corn co-products. This is then combined with membrane technology for the separation, isolation and purification of zein from the ethanolic zein solution. Membrane technology offers the possibility of selective low-energy low-cost separation of zein and for recycle of the ethanol solvent without the substantial evaporation costs that now limit other zein extraction processes. Additional economies are possible if COPE is carried out in corn-based ethanol plants since they already have the two key raw materials (corn and ethanol). Figure 2 shows one embodiment of the COPE process for zein which is described in a series of patents and research papers.

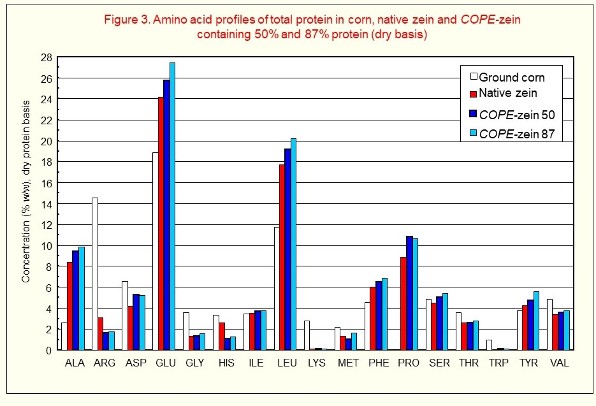

COPE can produce several grades of zein simultaneously, containing 50% protein to 90% protein (dry basis) and with varying amounts of color (xanthophylls). Typical amino acid profiles of two grades of COPE-zein are shown in Figure 3 and compared to the profiles of the total protein and native zein in corn.

Further refinements of the COPE process have been developed to extract additional high-value coproducts such as a "healthy" corn oil loaded with nutrients such as carotenoids, vitamins and phytosterols, and nutraceuticals such as xanthophylls (lutein and zeaxanthin). Because COPE products have not been exposed to the steeping chemicals and processing steps used for CGM, it is in a more “natural” state and thus has better functionality for certain applications. Our preliminary economic analysis shows a net revenue of $2-4/bushel corn ($0.07-0.15/kg of raw corn), depending on the coproduct(s). This translates into an additional income of $75-150 million per year for a plant producing 100 million gallons of ethanol/year (380 million liters/year) without any additional raw materials being used (we "borrow" in-house ground corn and ethanol). This technology has resulted in several US and Canadian patents and publications for the production of zein, oil and xanthophylls.

Publications and patents

Publications and patents